14, Raghava Enclave, Transport Road, Secunderabad, Hyderabad (500009)

©2024 All Rights Reserved by excitechrobot.com

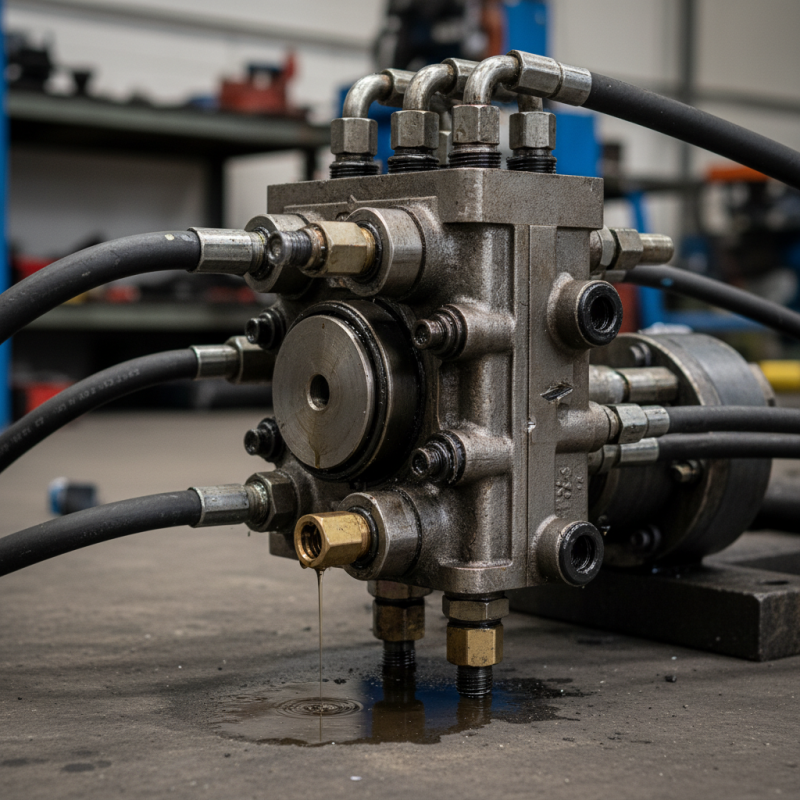

Troubleshooting an Overflow Valve Block can seem daunting. Often, it is the heart of hydraulic systems, regulating pressure and flow. When issues arise, it’s crucial to identify the underlying problems.

A malfunctioning overflow valve block can lead to inefficient operations. It can cause leaks, pressure drops, or unexpected shutdowns. These failures require specific attention and a methodical troubleshooting approach. Inspecting seals and connections is vital. Also, check for any visible damage or signs of wear.

Many overlook simple causes, complicating repairs. Understanding potential issues helps in narrowing down the problems. Every component has its role, so evaluating each carefully is necessary. Small details can provide significant insights into larger issues with the overflow valve block. Taking the time to investigate thoroughly can lead to effective resolutions and minimize downtime.

Identifying common symptoms of overflow valve block issues can save time and resources. One frequent sign is inconsistent pressure. If the pressure drops unexpectedly, it may indicate a blockage. Additionally, listen for unusual sounds. A grinding or hissing noise often reveals internal problems. Another symptom is fluid leaks, which can occur around the valve. Any visible leak points to a malfunction that needs addressing.

Consider the following tips. Regularly inspect the valve for buildup or dirt. Cleaning it can prevent many issues. Pay attention to the pressure gauge readings. They can offer insights into possible blockages. Keeping a log of maintenance helps track recurring problems, making identification easier.

Sometimes, troubleshooting is not straightforward. You might not find any visible issues, yet the system underperforms. In such cases, reviewing the entire hydraulic system can yield insights. Take the time to assess connections and hoses. They could contribute to the overall inefficiency. Identifying these symptoms early can prevent bigger headaches down the road.

Troubleshooting an overflow valve block can be daunting without the right tools. Essential tools include a multimeter to check electrical components, pressure gauges for measuring system pressure, and a flow meter to assess flow rates. According to industry reports, nearly 40% of overflow valve issues arise from improper pressure settings. Using accurate tools can significantly reduce diagnostic time.

A service manual is crucial for specific valve configurations. It provides diagrams and troubleshooting steps tailored to your device. Many technicians overlook the importance of following detailed schematics. This error can lead to misdiagnosis and prolonged downtime. Interestingly, 25% of repairs are delayed due to missing or unclear documentation. Thus, always keep your manuals handy.

Safety equipment should also be part of your toolkit. Gloves and safety goggles are necessary when dealing with hydraulic systems. Neglecting personal safety can lead to accidents, which is an often underestimated risk. Industry data reveals that equipment-related injuries account for 15% of workplace accidents. Taking precautions not only protects you but also ensures a more effective troubleshooting process.

This bar chart displays the frequency of various issues encountered while troubleshooting overflow valve blocks. Each problem is represented, highlighting the most common issues found during maintenance and inspections.

Inspecting an overflow valve can seem daunting. However, with a clear approach, the process becomes manageable. Begin by gathering your tools. You'll need a wrench, a flashlight, and a clean cloth.

Start with visual checks. Look for any signs of leakage around the valve. A small puddle can indicate a problem. Also, check for corrosion. This can suggest age or poor maintenance. Sometimes, the casing may look fine, but internal issues linger.

Once you have done the visual inspection, it’s time for functionality tests. Manually operate the valve. Listen for unusual sounds while you do this. A stuck or sluggish response can hint at internal problems. Clean any debris that may have collected. In many cases, a simple cleaning can resolve minor issues. However, if problems persist, a deeper inspection might be necessary. Ignoring these signs could lead to bigger issues down the line. Take your time and be thorough. Each step counts when it comes to efficiency.

Troubleshooting an overflow valve block requires clear testing techniques. Start with a visual inspection. Check for leaks or corrosion. Ensure all fittings are secure. Look for signs of wear on the valve itself. A neglected valve often shows physical signs before failing.

Next, check the valve's functionality. Apply pressure in a controlled manner. Observe how the valve responds. Does it open as expected? Note any unusual sounds. Sometimes, a simple adjustment can resolve issues.

Testing with machinery can reveal more details. Use gauge readings to verify performance. Is the pressure within acceptable limits? If not, there may be deeper issues at play. Recognizing these symptoms is key. Not all failures are obvious. Taking time to investigate thoroughly can save future headaches. Adjustments and repairs often stem from these early observations.

Preventing overflow valve block issues begins with understanding their common causes. A report from the Fluid Dynamics Institute noted that 40% of overflow valve failures stem from contamination. This contamination can come from dirt, debris, or even moisture in the fluid. Regularly inspecting and maintaining the fluid quality is essential. Simple practices like using filters can significantly reduce risks. Unfortunately, many users neglect this aspect, leading to costly repairs.

Another vital point is system pressure. Inadequate pressure can result in valve malfunctions. Research shows that maintaining proper system pressure can decrease overflow valve issues by nearly 30%. Operators often overlook pressure readings in their routine checks. A reliable pressure gauge is crucial. Regular calibration ensures accurate readings.

Training and awareness among operators also play a key role. Many incidents result from human error during maintenance. Providing your team with clear guidelines reduces mistakes. Visual aids can help. A simple poster showing steps for valve inspection can be effective. Ignoring these preventative measures could lead to recurring problems, highlighting the need for reflection and improvement in practices.