14, Raghava Enclave, Transport Road, Secunderabad, Hyderabad (500009)

©2024 All Rights Reserved by excitechrobot.com

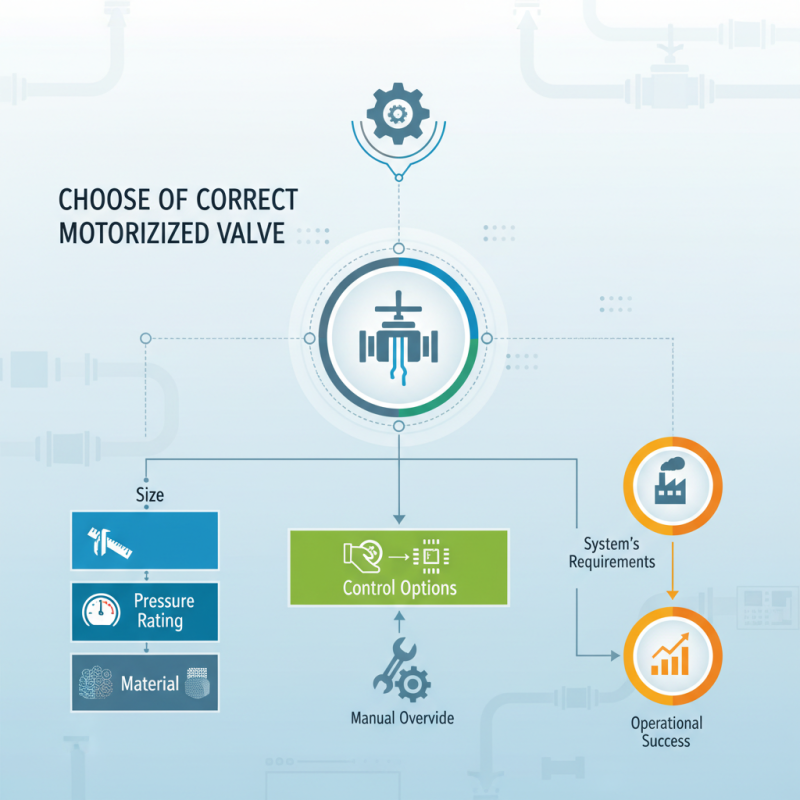

Choosing the right Motorized Valve can significantly impact your system's efficiency. These valves control fluid flow, affecting processes in various industries. Understanding what to look for is crucial.

Different types of motorized valves serve specific purposes. It's not just about the brand; the function and compatibility matter too. Consider the size, pressure rating, and material. For instance, an incorrect size could lead to leaks.

Additionally, think about the control options available. Some motorized valves offer manual override, which can be beneficial. Reflect on your system’s requirements carefully. These decisions shape your operational success. Don’t rush; take time to evaluate your needs.

Motorized valves play a crucial role in many industrial applications. They automate the control of fluid flow, making processes more efficient. These valves can be found in HVAC systems, water treatment plants, and even in manufacturing. Understanding their basic functions helps in choosing the right one.

When selecting a motorized valve, consider the medium it will control. Different fluids have unique properties. Some valves are better suited for harsh chemicals, while others work well with water or air. Size also matters. An oversized valve could lead to energy waste. Furthermore, think about ease of maintenance. A complex design might require more frequent servicing.

It’s essential to pay attention to the control type. Some valves use simple on/off controls, while others allow for precise modulation. Evaluate your application needs. A mismatch can cause issues. Reflect on your system's requirements and potential upgrades. These factors will guide you toward a suitable motorized valve choice.

When selecting a motorized valve, several key factors come into play. The valve size is crucial. It needs to match the application requirements. A valve too small can cause flow restrictions. Conversely, an oversized valve may lead to inefficiencies. According to industry reports, nearly 30% of energy loss in systems is due to improperly sized valves. Always consider the flow rate and pressure.

Another important factor is the valve material. The environment dictates the best choice. Corrosion resistance is vital in harsh settings. Stainless steel is popular for its durability. However, it may not be ideal for all applications. Some materials are more cost-effective but less resilient. Assessing the specific fluid type is essential. For example, chemicals may require specialized materials to prevent leaks or degradation.

Tips for ensuring the right choice:

- Assess the operating conditions thoroughly. Understand the temperature and pressure limits.

- Consider the actuator type. Electric actuators offer precision but may need specific power sources.

- Evaluate the control options. Manual, automatic, or remote-controlled setups work differently in practice.

Remember that not every valve fits every situation. Often, users might overlook compatibility with existing systems. This oversight can lead to operational challenges. Always reflect on system needs before making a selection.

| Factor | Description | Importance Level |

|---|---|---|

| Size and Type | Identify the required size and type based on the application needs. | High |

| Material | Choose materials compatible with the fluids involved to avoid corrosion. | Medium |

| Control Type | Determine whether an on/off or modulating control is required. | High |

| Voltage Rating | Ensure the valve operates within the appropriate voltage supply levels. | High |

| Response Time | Assess the required response time for operational efficiency. | Medium |

| Environmental Conditions | Consider temperature, pressure, and other environmental factors that may affect performance. | High |

When selecting motorized valves, understanding the types available is crucial. There are various categories, including globe valves, ball valves, and butterfly valves. Each type serves distinct purposes in fluid control. For instance, globe valves are often used in applications requiring precise flow regulation. According to a 2022 industry report, they account for around 30% of the motorized valve market due to their reliability.

Ball valves, on the other hand, are known for their quick shut-off capabilities. They are ideal for pipelines that need to be closed rapidly. This type of valve represents roughly 40% of the market share. A study indicated that businesses have seen up to a 25% increase in efficiency when using ball valves in high-demand settings. Butterfly valves, with their lightweight design, are favored in large volumes where space is limited. They hold a smaller share, around 15%, but are invaluable in HVAC and water treatment applications.

Selecting the right motorized valve can be overwhelming. Factors like pressure, temperature, and flow rate must be considered. Misjudgments could lead to leaks or equipment failure, which can be costly. Some organizations mistakenly prioritize price over quality, leading to issues down the line. These decisions should be informed, not rushed. Taking the time to evaluate the appropriate type can prevent future headaches.

This bar chart illustrates the suitability scores of different types of motorized valves for various applications. Electric actuated valves are seen as most suitable, while hydraulic actuated options have a lower score.

When selecting a motorized valve, it's crucial to evaluate its specifications and features. The flow rate is a key parameter. A typical motorized valve can handle rates from 0.5 to 100 gallons per minute. This range affects the valve's efficiency and applications. If you're working on a system requiring high flow, ensure the valve matches those needs. Some manufacturers provide technical datasheets outlining performance curves. Evaluate these carefully.

Material is another critical factor. The body of the valve might be brass, stainless steel, or plastic. Each material has strengths and weaknesses. For example, brass valves resist corrosion but may not suit all chemicals. On the other hand, plastic valves can be lighter and cheaper but might not handle high temperatures well.

Actuation type also deserves attention. Some valves use electric actuators, while others might employ pneumatic or hydraulic types. Electric actuators are common due to their precision but can face efficiency issues in extreme temperatures. Analyze your environment and system requirements.

Some users report failure due to improper sizing. Oversized valves can lead to turbulence and reduce efficiency. Research shows that 30% of valve failures are due to such mismatches. It's essential to choose the right size and type. Don't overlook installation and maintenance either; these aspects significantly influence the overall performance and longevity of the motorized valve.

When selecting a motorized valve, the manufacturer’s reputation plays a pivotal role. Reports indicate that 70% of customers prioritize after-sales support when making a buying decision. A reliable manufacturer ensures timely service and maintenance, which prolongs the lifespan of the valve. This aspect is crucial, as improper maintenance can lead to costly system failures.

Tips for choosing a valve: Always check for customer reviews and testimonials. A company’s track record can provide insight into its reliability. Look for manufacturers who offer comprehensive warranties. These reflect confidence in their product quality and support.

Another critical factor is the availability of technical support. A study shows that 65% of users value a manufacturer’s responsiveness. Delays in getting help can negatively affect your operations. Ensuring the manufacturer has knowledgeable staff can make a significant difference. Consider reaching out to them with questions prior to purchase. This interaction can reveal their commitment to customer service.