14, Raghava Enclave, Transport Road, Secunderabad, Hyderabad (500009)

©2024 All Rights Reserved by excitechrobot.com

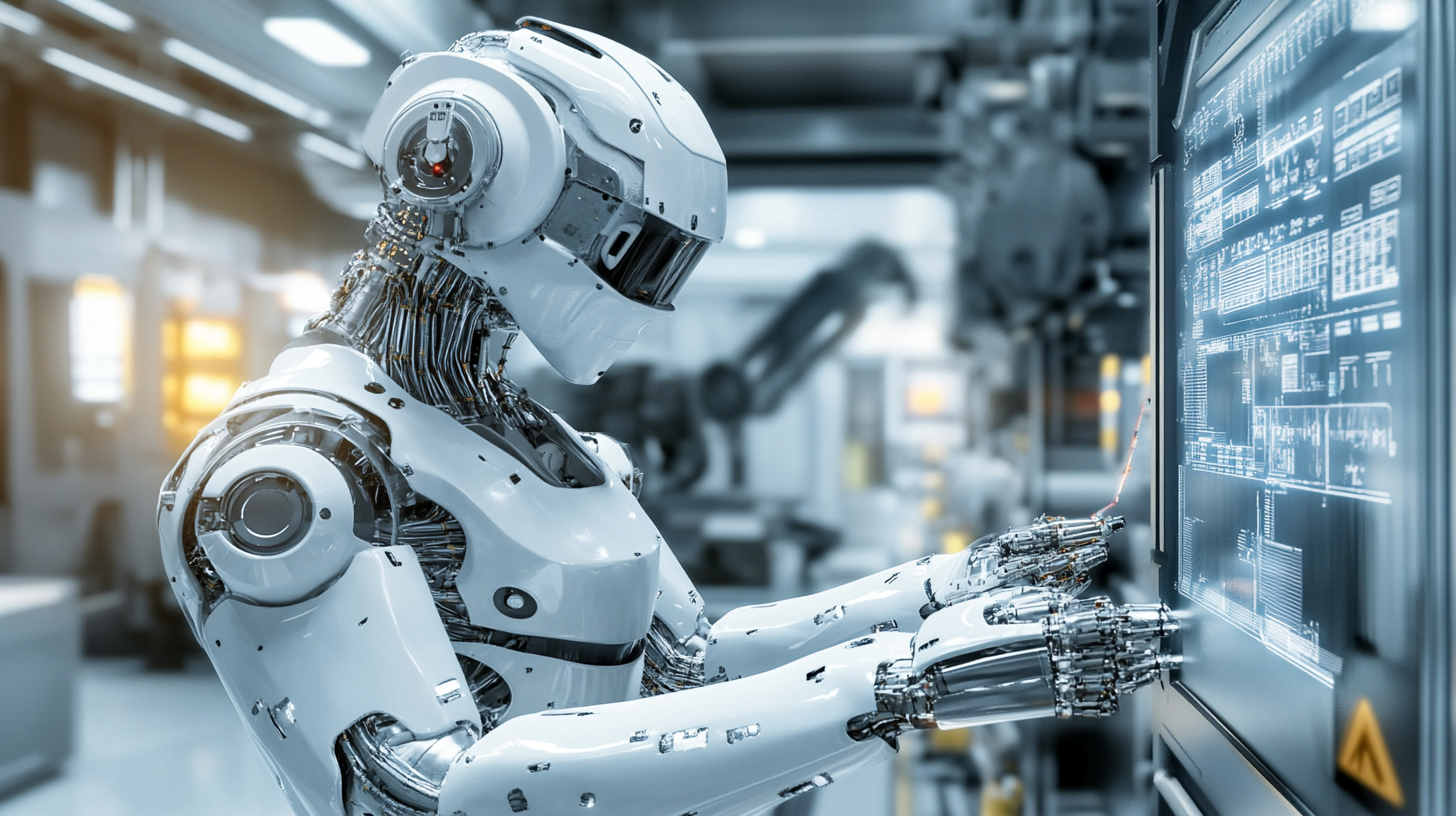

In today's fast-paced manufacturing landscape, the integration of robotic systems has revolutionized various processes, enhancing efficiency, precision, and productivity. These advanced technologies not only streamline operations but also reduce human error and operational costs, making them invaluable assets in the industry. This blog will explore real-world applications of the best robotic systems currently transforming manufacturing environments. We will delve into specific examples of how companies across different sectors are leveraging these innovative technologies to optimize production lines, improve quality control, and respond to market demands more swiftly. Additionally, we will provide insights into the implementation processes, guiding manufacturers on how to seamlessly integrate robotic systems into their operations for maximum impact. Whether you are a seasoned industry leader or a newcomer eager to adopt automation, understanding these applications will be crucial in navigating the future of manufacturing.

In today's fast-paced manufacturing landscape, the integration of robotic systems has revolutionized various processes, enhancing efficiency, precision, and productivity. These advanced technologies not only streamline operations but also reduce human error and operational costs, making them invaluable assets in the industry. This blog will explore real-world applications of the best robotic systems currently transforming manufacturing environments. We will delve into specific examples of how companies across different sectors are leveraging these innovative technologies to optimize production lines, improve quality control, and respond to market demands more swiftly. Additionally, we will provide insights into the implementation processes, guiding manufacturers on how to seamlessly integrate robotic systems into their operations for maximum impact. Whether you are a seasoned industry leader or a newcomer eager to adopt automation, understanding these applications will be crucial in navigating the future of manufacturing.

The manufacturing industry is undergoing a transformative shift with the integration of advanced robotic systems. Current trends highlight the rapid growth of smart manufacturing in the U.S., with the market projected to rise from $66.18 billion in 2023 to an impressive $145.57 billion by 2030. This significant growth is driven by innovations that enhance productivity, efficiency, and flexibility in production lines, marking a pivotal moment for manufacturers to adopt robotic solutions.

To implement these robotic systems effectively, businesses should consider the following tips:

First, assess your specific production needs to identify which robotic technologies can best enhance your operations. Whether it’s automation in assembly lines or the use of collaborative robots alongside human workers, a tailored strategy is essential.

Second, invest in training and development for your workforce. Ensuring that employees understand how to work alongside robots will facilitate smoother integration and maximize productivity gains.

Finally, keep an eye on global trends, particularly in humanoid robotics, where companies in regions like China take a leading role. Understanding the competitive landscape can help U.S. manufacturers leverage innovations from abroad and stay ahead in the market. Adapting to these advancements will not only improve operational effectiveness but also position manufacturers favorably for future growth.

In today's manufacturing landscape, the integration of robotic systems is essential for enhancing efficiency and productivity. When evaluating robotic solutions, there are several key features to prioritize. First and foremost, flexibility is crucial. Modern manufacturing environments often have fluctuating demands, and robots that can adapt to various tasks without extensive reprogramming or downtime can significantly improve operational throughput. Look for robots equipped with advanced software and modular hardware that allow for quick reconfiguration to handle different products or processes.

Another important feature is precision and reliability. Manufacturing operations depend on consistent quality, and robots that can perform tasks with high accuracy ensure minimal errors and waste. Technologies such as machine vision and AI-driven analytics can greatly enhance a robot’s ability to identify defects and adjust operations in real time. Additionally, ease of integration with existing systems, such as ERP and SCM software, should not be overlooked. A seamless connection ensures that robots can communicate effectively with other manufacturing technologies, allowing for smooth workflow and better coordination across various stages of production.

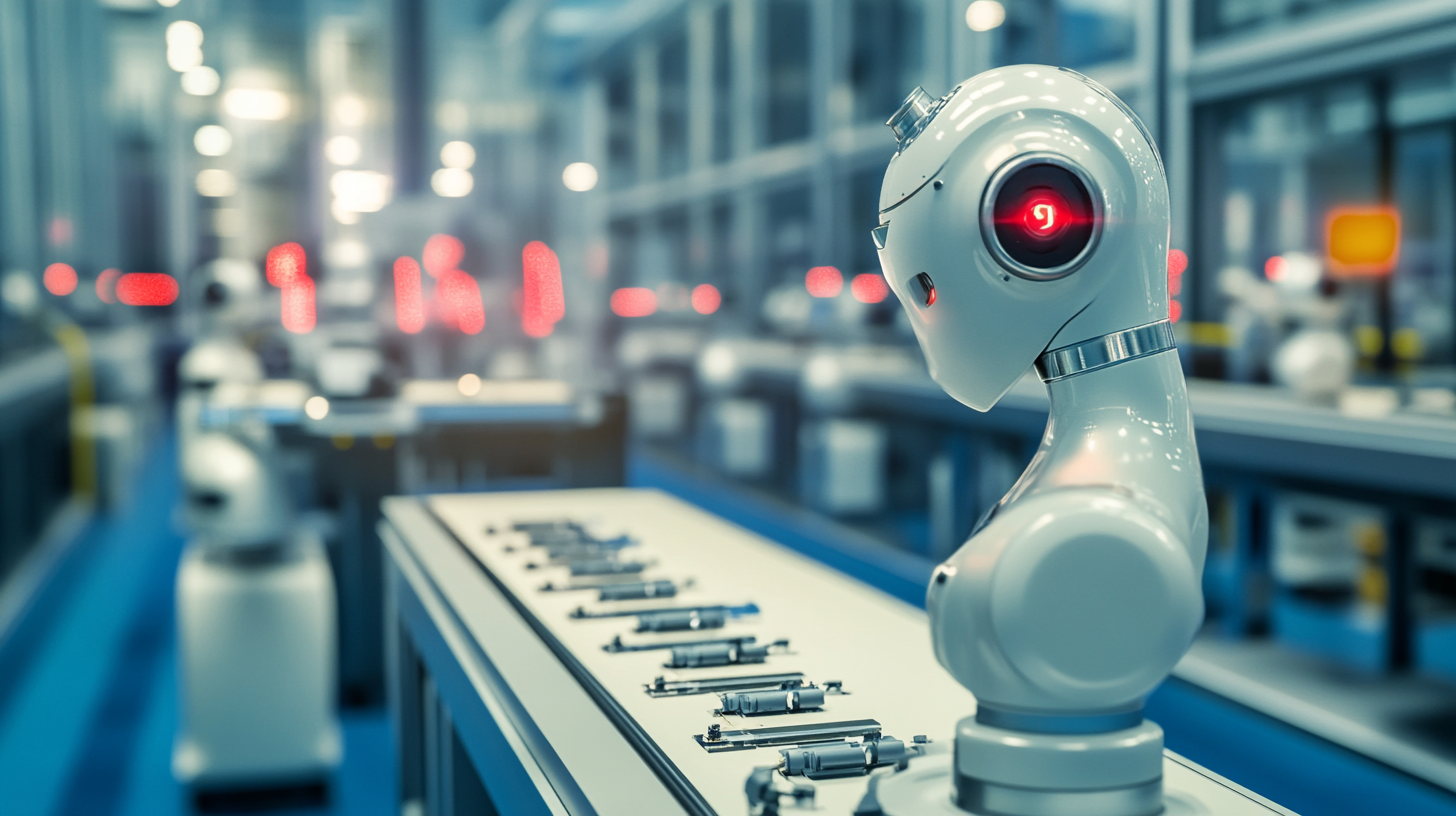

In contemporary manufacturing, implementing robotic systems can significantly streamline operations, enhance efficiency, and improve employee safety. A recent report highlights that companies deploying robotics, such as advanced collaborative robots, have seen substantial gains in productivity. For instance, logistics firms have integrated over 750,000 robots to assist with sorting, lifting, and carrying packages, demonstrating their critical role in meeting consumer demands while allowing human workers to focus on more complex tasks.

To effectively implement robotic systems in your facility, follow a step-by-step approach. First, assess your current workflow and identify repetitive tasks that can be automated. Next, invest in pilot programs to test various robotic technologies. Notably, facilities are increasingly leveraging artificial intelligence alongside robotics to create next-generation fulfillment centers, reimagining ways to enhance both employee and customer experiences. By ensuring that your robotic systems work in harmony with human workers, you can achieve an efficient and productive operation that responds adeptly to market demands.

In the rapidly evolving landscape of robo-manufacturing, industries face several challenges that can hinder the implementation of robotic systems. One major obstacle is the initial investment cost. Many manufacturers hesitate to adopt robotics due to the high upfront expenditure involved in purchasing and integrating these systems. However, it's crucial to view this as a long-term investment rather than an expense.

**Tip:** Consider starting with a phased approach to implementation. Begin with one or two robotic systems that target specific repetitive tasks. This will allow you to assess the benefits and scalability of the technology without overwhelming your budget.

Another common challenge in robo-manufacturing is workforce adaptation. Employees may feel threatened by the introduction of robots, fearing job loss or skill redundancy. To combat these fears, manufacturers should prioritize employee training and engagement.

**Tip:** Implement comprehensive training programs that focus on upskilling workers to work alongside robotic systems. Emphasizing collaborative robotics can enhance productivity while fostering a culture of innovation, ensuring that your workforce is not only compatible with technology but also empowered by it.

| Application Area | Robotic System Type | Common Challenges | Proposed Solutions |

|---|---|---|---|

| Assembly Line Operations | Collaborative Robots (Cobots) | Safety concerns, Integration with human workers | Improved safety protocols, Enhanced training sessions |

| Welding Processes | Industrial Robotic Arms | Precision issues, Equipment costs | Regular calibration, Investment in high-quality robots |

| Material Handling | Automated Guided Vehicles (AGVs) | Navigation difficulties in complex environments | Advanced mapping technologies, Regular maintenance |

| Quality Control | Vision Systems | False positives/negatives, Integration with existing systems | Machine learning algorithms, Customized integration support |

| Packaging and Palletizing | Robotic Palletizers | Variability in product dimensions | Adaptive gripper technologies, Flexible programming |

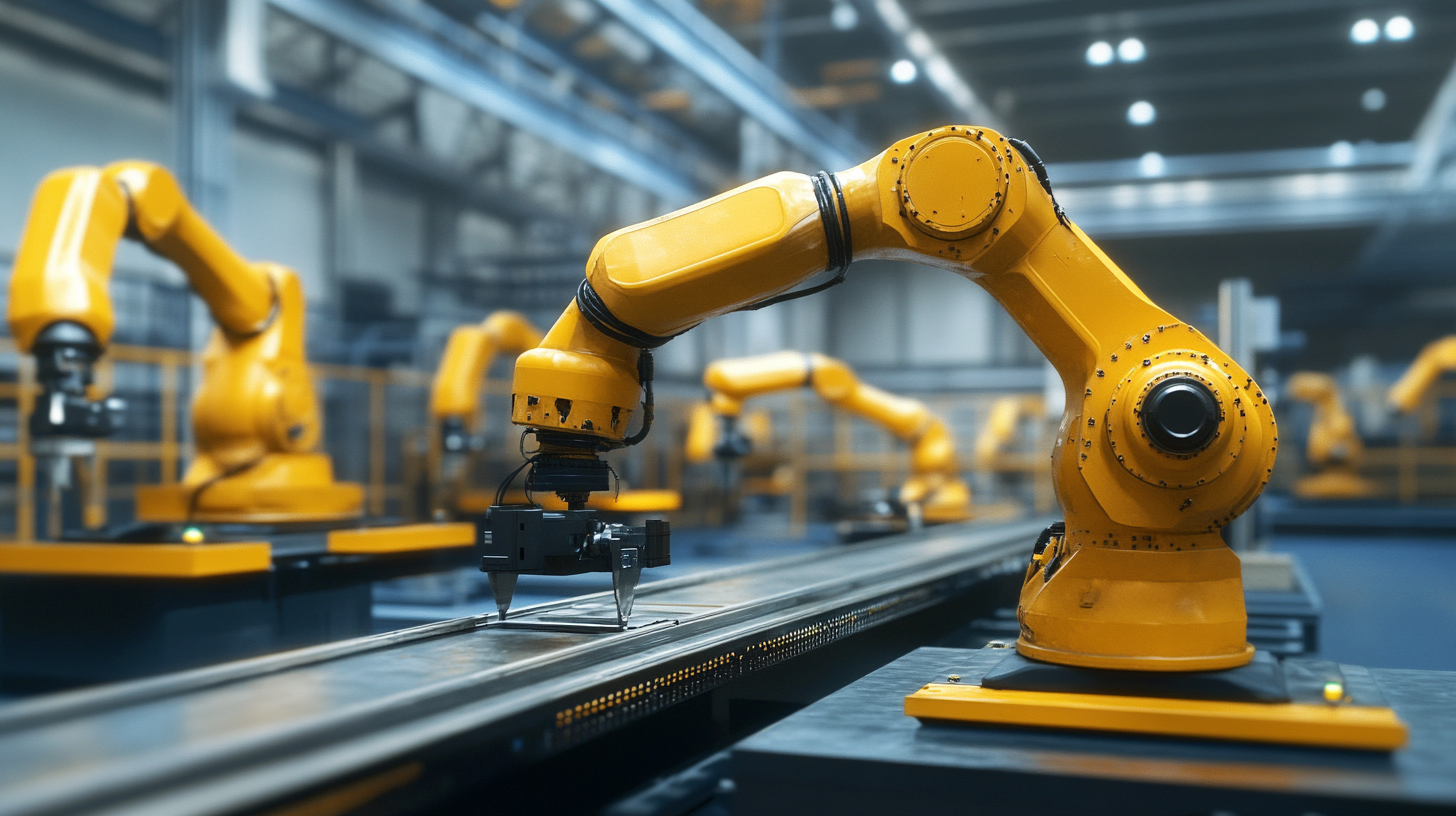

In the realm of manufacturing, the integration of robotic systems has led to remarkable increases in efficiency and productivity. A recent report by McKinsey indicates that the adoption of automation in manufacturing could boost global productivity by up to 1.4% annually. Companies like Tesla and Amazon serve as prime examples, showcasing the successful implementation of robots in their factories. Tesla, for instance, leverages advanced robotic systems in their assembly lines, which has enabled them to produce vehicles at an unprecedented rate, reducing overall production time considerably.

Moreover, the case of Fanuc, a leading robotics manufacturer, highlights the benefits of collaborative robots (cobots) in production. According to a 2022 report by the International Federation of Robotics, the use of cobots in factories has increased dramatically, with a projected growth rate of over 30% by 2025. Fanuc's integration of cobots alongside human workers has not only enhanced operational flexibility but also ensured safety and efficiency, allowing for the seamless handling of repetitive tasks. Such real-world applications demonstrate how strategic implementation of robotic systems can lead to significant advancements in manufacturing processes.