14, Raghava Enclave, Transport Road, Secunderabad, Hyderabad (500009)

©2024 All Rights Reserved by excitechrobot.com

In today's manufacturing landscape, the integration of Rapid Robotics is becoming essential. According to a recent report by the International Federation of Robotics, 2022 saw a 25% increase in robotic installations in manufacturing. This surge reflects the urgent need for efficient operations and cost reduction. Rapid Robotics represents a critical advancement in this area, enabling manufacturers to streamline their processes with agility.

Experts like Dr. Emily Chen, a leading figure in the field of robotics, emphasize the importance of this technology. She stated, "Rapid Robotics transforms traditional manufacturing, allowing for greater speed and flexibility." This shift is crucial as manufacturers face growing competition and changing market demands. The adoption of Rapid Robotics can lead to increased productivity and lower labor costs, but it is not without challenges.

Implementing these systems requires careful planning and training. Many businesses hesitate due to upfront costs or fear of disruptions. Striking a balance between technology and human labor remains a challenge. The future of manufacturing will likely hinge on the successful integration of Rapid Robotics, despite the hurdles that may arise.

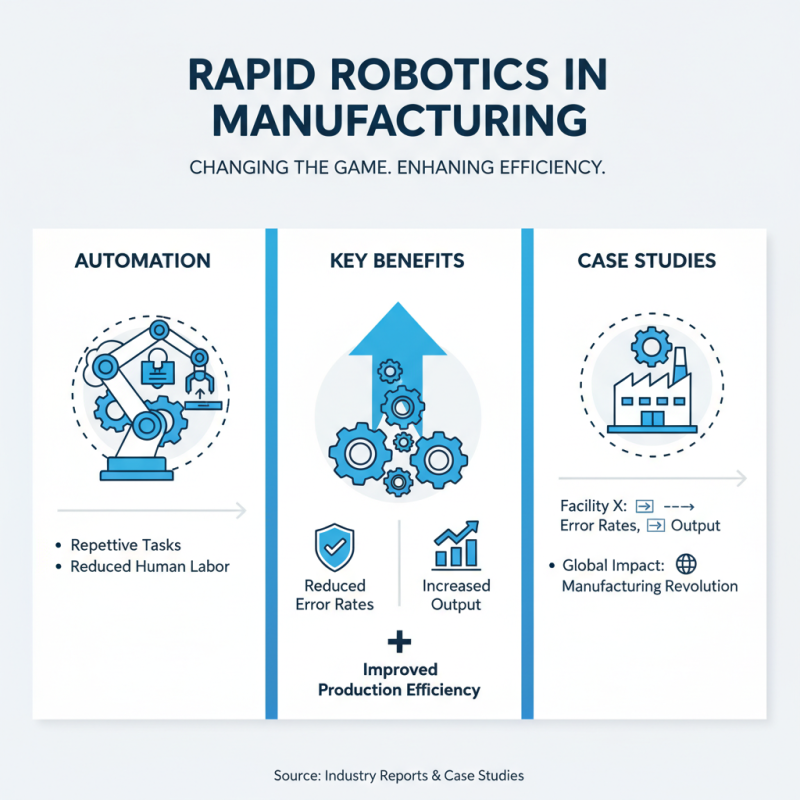

In recent years, the use of robotics in manufacturing has dramatically increased. Companies seek ways to streamline processes and reduce costs. Rapid robotics are a game changer. They can perform repetitive tasks with high precision. Efficiency and productivity surge when machines take over mundane tasks.

Tips: Start by identifying bottlenecks in your workflow. This will help in selecting the right robotic solutions. Ensure your team receives proper training. Familiarity with robotics can enhance productivity. Evaluate the progress regularly. Small adjustments can lead to significant improvements.

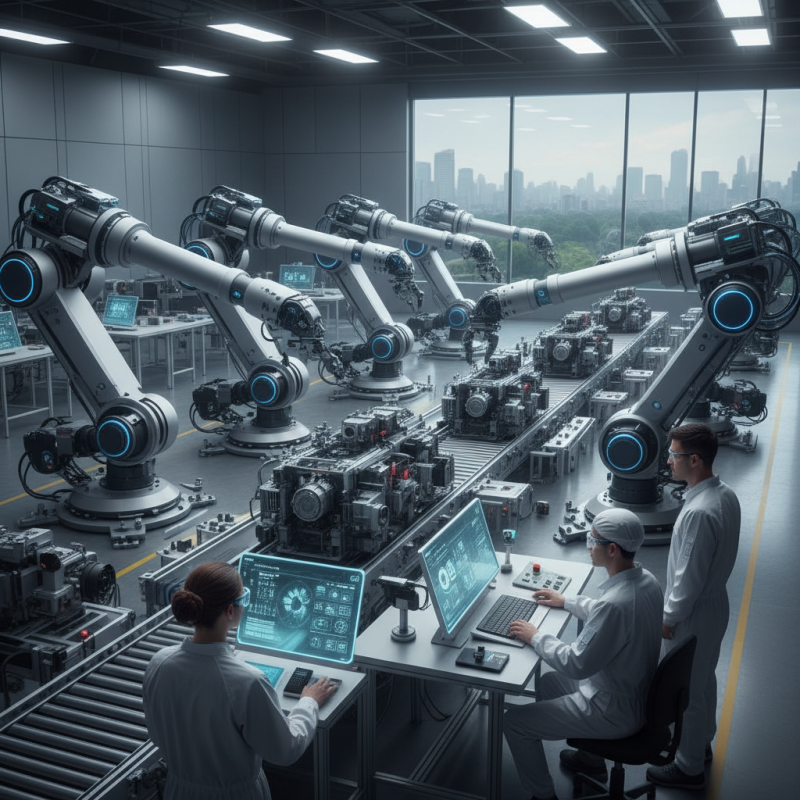

Current trends show a rise in collaborative robots, or cobots. These machines work alongside human workers. They help in assembly lines and packaging. However, not all tasks are suited for automation. Some processes may require the human touch. Balancing human effort and machine efficiency is essential. Consider the potential downsides. Over-reliance on technology might result in job displacement. It's crucial to strike a balance.

The introduction of rapid robotics in manufacturing is changing the game. Case studies show how these technologies enhance production efficiency. In one facility, robots managed repetitive tasks that once required significant human labor. This switch reduced error rates and increased output.

However, the transition is not without its challenges. Workers may feel threatened by automation. Training becomes essential to ensure that human workers adapt and thrive alongside robots. In another example, a company faced downtime during the initial rollout. Adjustments in workflow were necessary to integrate robotic systems effectively.

Data reveals impressive results. Production processes became 30% faster on average with robots. Yet, relying solely on automation can lead to oversights. Human intervention remains critical in quality control. Balancing robotics and skilled labor is a continuous journey.

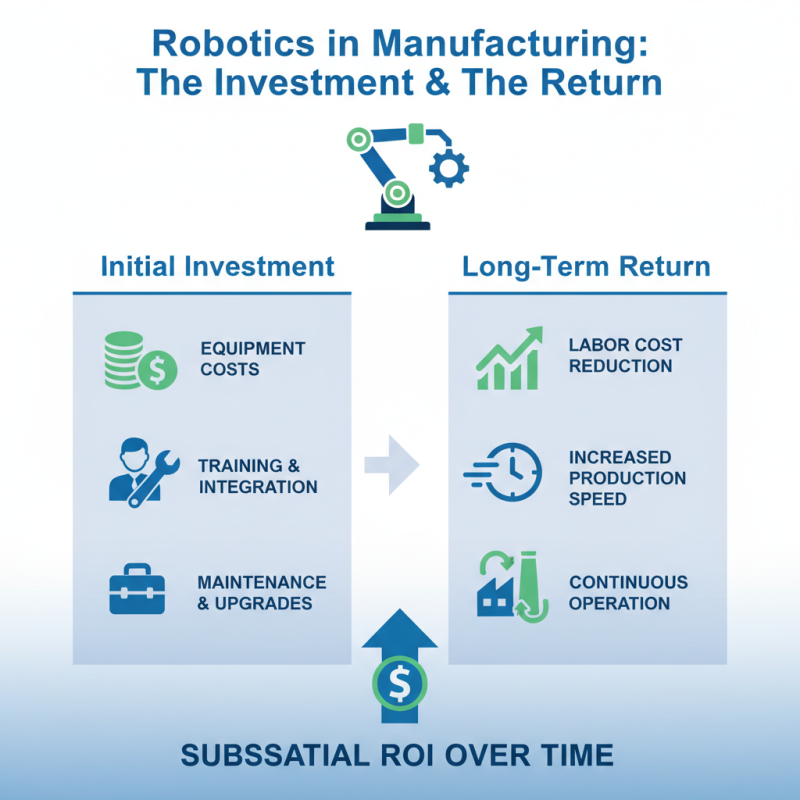

Implementing robotic solutions in manufacturing can provide substantial advantages. The initial investment may be significant. Companies must consider equipment costs, training, and maintenance. Yet, the return on investment can be impressive over time. Automating routine tasks can drastically reduce labor costs. Robots work faster and can operate continuously.

Many manufacturers notice improved efficiency quickly. They can produce goods at higher rates while ensuring consistent quality. However, it’s vital to evaluate if all processes are suitable for automation. Not every task benefits from robotic solutions. Some operations still require human oversight. Moreover, the transition can be challenging. Workers may need time to adjust to new technology.

Harvesting the benefits of robotics requires careful planning. Also, businesses must assess their specific needs. An extensive analysis of costs and benefits can uncover potential pitfalls. Companies should not overlook possible downtime during the transition. While robotic solutions hold promise, each manufacturer’s situation is unique. A thoughtful approach can lead to successful integration.

Integrating rapid robotics into manufacturing requires careful planning. Adoption can be overwhelming. Start with a thorough assessment of your current processes. Identify bottlenecks or repetitive tasks that are perfect for automation. This will make the transition smoother and more effective.

Training your workforce is crucial. Workers may feel threatened by robotic systems. Address their fears with open communication. Host workshops to showcase how robots will assist them, not replace them. Encourage feedback during the integration phase. It allows for necessary adjustments and helps build trust.

Pilot programs can be beneficial. Implement robotics in small, controlled environments first. Monitor performance closely. Expect challenges; not everything will go as planned. Each hiccup offers an opportunity for improvement. Regularly adapt your strategy based on these lessons. This fosters an adaptive culture, ensuring long-term success in your robotics journey.

The manufacturing landscape is evolving rapidly due to innovations in robotics. Smart robotics are central to this change. With advanced sensors and AI, robots are more versatile. They now handle complex tasks, improving efficiency. This shift is not just a trend; it’s a revolution.

Tips: Invest in training your workforce. Understanding robotics is essential. Provide employees with skills to operate and collaborate with machines. Experiment with different robotic systems. Not every solution fits every need. Ensure your processes align with your specific goals.

Moreover, as automation rises, so does the need for adaptability. Robotics can reduce labor costs but may also introduce challenges. Maintenance and updates necessitate constant attention. Businesses must continually evaluate their robotic integrations. What worked yesterday might not suffice tomorrow.