14, Raghava Enclave, Transport Road, Secunderabad, Hyderabad (500009)

©2024 All Rights Reserved by excitechrobot.com

Choosing the right Rubber Pump Impeller is crucial for efficiency. According to a report from the Pump Manufacturers Association, improper selection can lead to a 20% drop in performance. "Efficiency hinges on the right choice of impeller," says industry expert Dr. Emily Rivera. Many users overlook material properties.

Different applications require specific characteristics. A flexible rubber impeller can handle abrasive fluids effectively. However, others may need a hard material for high-pressure scenarios. Without proper knowledge, mistakes can happen.

Your decision impacts operational costs and maintenance. Selecting the wrong Rubber Pump Impeller may cause increased wear or frequent replacements. Awareness and understanding of requirements are vital for success. Striving for the best fit will yield the best results.

Understanding rubber pump impellers is essential for anyone in the pumping industry. These components play a critical role in the efficiency and reliability of pump systems. The right impeller reduces wear and tear, leading to lower maintenance costs. According to industry reports, choosing the right material can improve performance by up to 30%. Rubber impellers are often favored for their flexibility and durability in diverse applications.

When selecting a rubber pump impeller, consider the operating conditions. Factors such as fluid type, temperature, and pressure are vital. A mismatch in material can lead to premature failure. Research indicates that over 40% of pump failures are related to improper impeller choices. Inadequate knowledge of these factors may lead to costly downtime and inefficient operations.

Additionally, the design of the impeller affects flow rates and efficiency. The geometry needs to suit specific tasks. Slight variances in design can yield different performance results. It's not uncommon for engineers to overlook these details, leading to frustration later. Regular evaluations and updates to selection criteria can mitigate these risks. Understanding the basics can guide better decision-making in the long run.

Choosing the right rubber pump impeller hinges largely on understanding your specific pumping requirements. Are you moving water or abrasive materials? The type of fluid determines the impeller material. A rubber impeller may suit water, but you'll need something sturdier for gritty substances.

Consider flow rate. How much fluid do you need to move? An inadequate flow can lead to inefficiency. If your needs change often, a flexible design might be ideal. Pay attention to the size and speed of the pump as well. Oversized impellers can overwhelm a system, while undersized ones can struggle to meet demands.

Keep in mind the environment where the pump operates. Temperature and pressure can impact performance. Take a moment to evaluate your past experiences with pumps. Did a previous choice lead to frequent breakdowns? Reflection can guide better decisions. Adjusting your approach based on this insight is essential for improvement.

When evaluating the material properties of rubber impellers, several factors come into play. Rubber impellers are valued for their flexibility and resistance to abrasion. According to industry reports, a high-grade rubber impeller can endure temperatures up to 200°F while maintaining performance. This resilience is crucial in many fluid transfer applications.

Different rubber compounds have unique strengths. For instance, nitrile rubber offers excellent oil resistance but may not perform well under extreme temperatures. Natural rubber, on the other hand, provides better elasticity but can degrade faster when exposed to certain chemicals. It’s essential to assess the operating environment when selecting the material. Misjudging this can lead to premature failures, resulting in unexpected downtimes.

Additionally, the hardness of rubber impellers, measured in Shore A scale, affects their performance. Softer rubber provides better grip, while harder compositions can withstand heavy loads. Research indicates that an optimal Shore A hardness rating for most applications ranges between 60 to 70. Poor material selection could mean inefficiency and increased costs over time. Thus, a thorough evaluation of each application’s requirements is critical.

| Material Type | Durometer Rating | Temperature Resistance (°C) | Chemical Resistance | Applications |

|---|---|---|---|---|

| Natural Rubber | 40-60 Shore A | -20 to 80 | Water, dilute acids | Water pumps, general applications |

| Nitrile (Buna-N) | 60-90 Shore A | -25 to 100 | Oil, fuels, hydrocarbons | Fuel pumps, oil applications |

| EPDM | 50-80 Shore A | -40 to 120 | Alkalis, weather, ozone | Wastewater treatment |

| Silicone | 30-70 Shore A | -60 to 200 | None, excellent for food grade | Food processing, pharmaceutical |

| Polyurethane | 70-90 Shore A | -30 to 80 | Abrasion, oil, chemicals | Heavy-duty applications, industrial pumps |

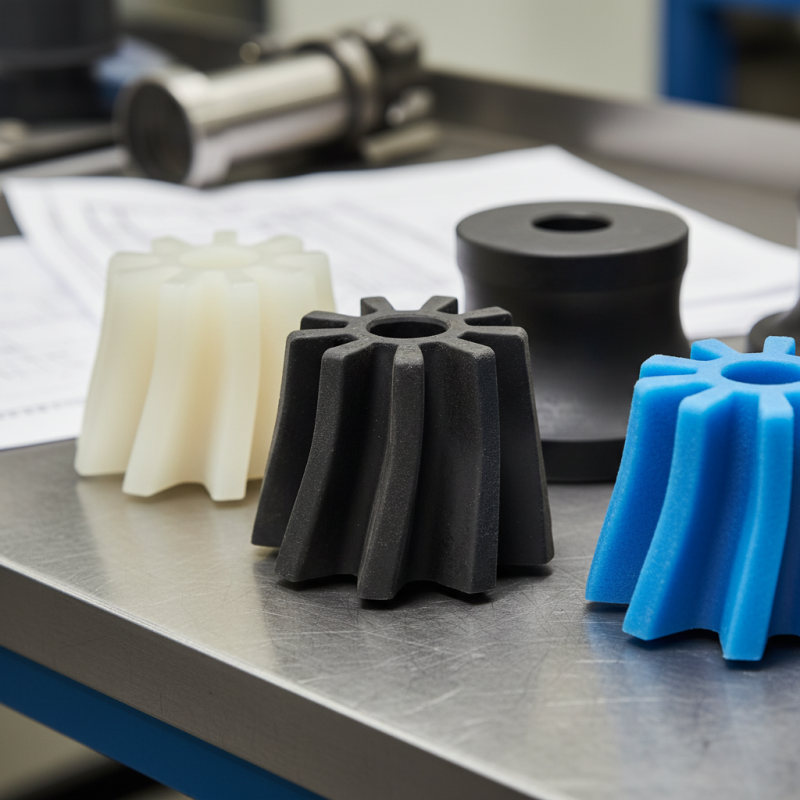

Choosing the right rubber pump impeller is crucial for efficiency. Different designs and configurations can have significant effects on performance. For instance, open impellers offer high flow rates but can struggle with solids. Closed impellers deliver better efficiency but may clog more easily. The choice often balances between these trade-offs.

According to industry reports, nearly 30% of pump failures stem from improper impeller selection. A recent study highlighted that open impellers are often favored in applications with clean liquids. Conversely, closed configurations excel in environments with particulates. This mismatch can lead to costly downtimes and maintenance.

Another consideration is the material of the impeller. Rubber compounds vary widely in hardness, flexibility, and chemical resistance. For example, a softer rubber may wear out faster but can handle impacts better. On the other hand, harder rubber provides longevity but may be less versatile in harsh conditions. Determining the right material requires careful analysis of the specific application needs.

When selecting a rubber pump impeller, maintenance and replacement are critical factors. Many industry reports indicate that improper maintenance can reduce impeller lifespan significantly. According to a recent study, over 30% of pump failures result from neglecting regular checks. Regular inspections help to identify wear and signs of damage early.

Tips: Keep a maintenance log. Schedule monthly inspections. Monitor vibrations closely. These practices can enhance the longevity of your impeller. It's also essential to check for any signs of deterioration, as this could signal potential issues.

Replacement is another important aspect. Depending on usage, an impeller should be replaced every one to three years. Environmental factors, such as temperature and abrasion, can accelerate wear. A recent industry survey found that 45% of facilities overlook these conditions, leading to inadequate performance. Take time to assess your operating environment and adjust maintenance schedules accordingly. Not all rubber materials are created equal; some suit specific applications better than others. Make sure to choose accordingly.

This bar chart illustrates the performance of different types of rubber pump impellers based on their maintenance frequency and average lifespan. Choosing the right impeller is crucial for minimizing downtime and ensuring efficient operation.