14, Raghava Enclave, Transport Road, Secunderabad, Hyderabad (500009)

©2024 All Rights Reserved by excitechrobot.com

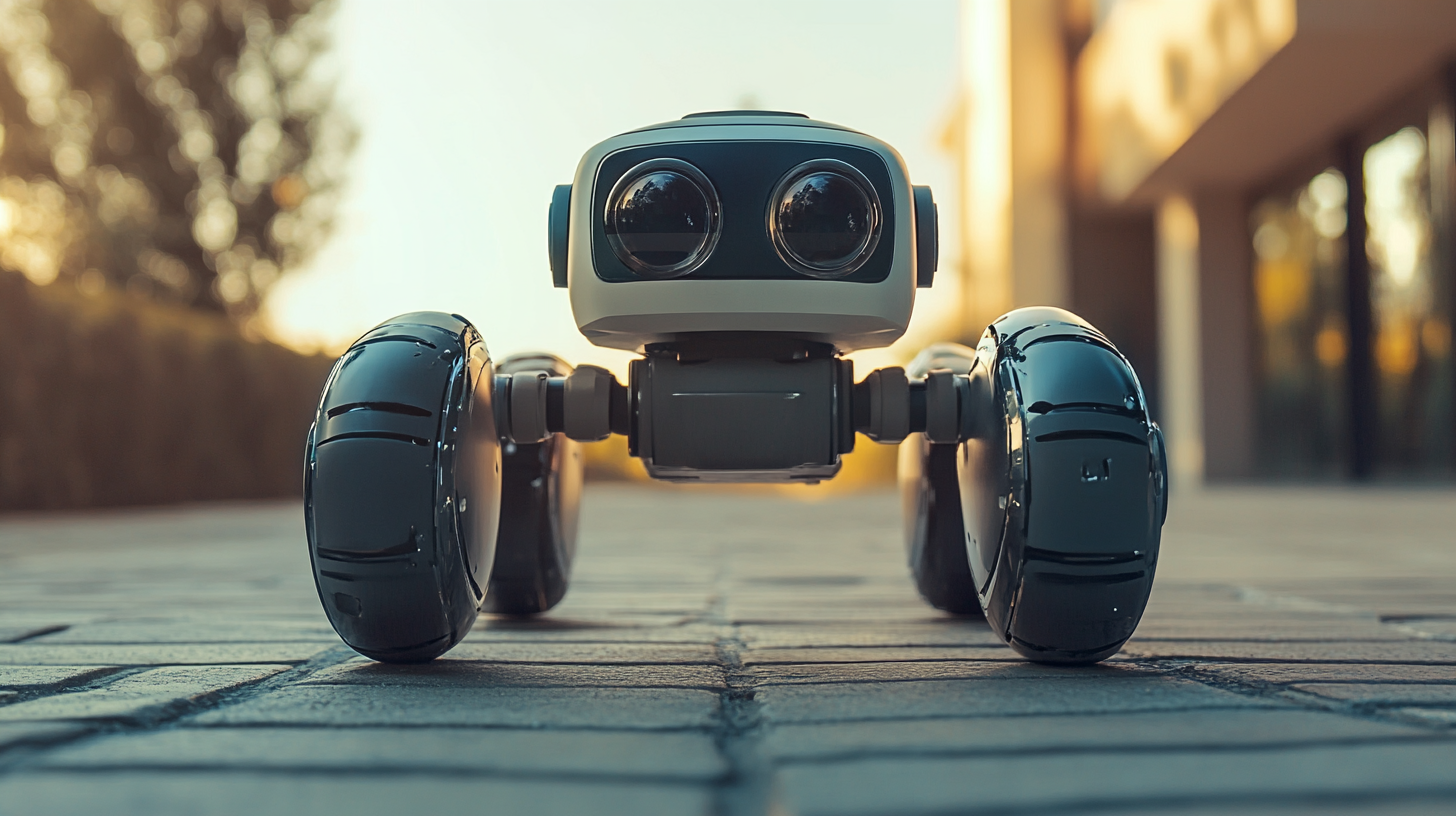

In recent years, the integration of technology into business operations has accelerated, with Autonomous Mobile Robots (AMRs) standing out as a transformative force across various industries. According to a report by ResearchAndMarkets, the global market for AMRs is projected to reach $15 billion by 2027, growing at a CAGR of over 25% from 2020. This rapid growth underscores the increasing acceptance of AMRs as essential tools for enhancing operational efficiency, reducing labor costs, and improving accuracy in logistics and warehousing.

Businesses are increasingly recognizing the value that AMRs bring, not only to streamline processes but also to adapt to the evolving demands of consumer expectations and supply chain challenges. A study by the International Federation of Robotics revealed that 66% of companies using robots reported significant improvements in their productivity and operational efficiency. As businesses grapple with the need for agility amid rising competition and a shifting economic landscape, implementing Autonomous Mobile Robots is no longer a luxury but a necessity for those aiming to sustain growth and stay ahead in their markets.

Autonomous mobile robots (AMRs) are increasingly recognized as game changers for enhancing business efficiency across various industries. According to a report by Logistics Management, businesses that implement AMRs can expect a productivity increase of up to 30%. These innovative machines navigate autonomously, allowing them to transport materials and goods throughout warehouses and manufacturing plants without the need for human intervention. This capability not only minimizes operational bottlenecks but also frees up employees to focus on more strategic tasks. The impact of AMRs extends beyond just increased productivity. A study conducted by the Research and Markets reveals that the global market for industrial robots, particularly AMRs, is projected to reach approximately $47 billion by 2025, reflecting a compound annual growth rate (CAGR) of 18.4%. This surge is driven by the need for businesses to streamline operations, reduce operational costs, and respond more agilely to customer demands. By automating repetitive tasks, AMRs provide companies with the competitive edge needed to thrive in today’s fast-paced market. Furthermore, AMRs contribute significantly to improving workplace safety. According to a report by the National Institute for Occupational Safety and Health (NIOSH), businesses that implement robotics can reduce workplace injuries by up to 50%. With fewer human-operated machines and vehicles in the workspace, the risk of accidents decreases dramatically, fostering a safer work environment. This integration of technology not only supports efficiency but also reinforces a commitment to employee wellbeing and safety.

Autonomous mobile robots (AMRs) have emerged as a transformative technology across various industries, significantly enhancing operational efficiency. One of the key benefits of implementing AMRs is their ability to streamline logistics and material handling processes. In warehouses, for instance, AMRs can navigate through aisles, transporting goods from one location to another, thereby reducing the time spent on manual labor. This not only speeds up order fulfillment but also minimizes the risk of human errors, ensuring a more accurate inventory management system.

Another significant advantage of utilizing AMRs is their capability to operate around the clock. Unlike traditional workforce solutions, which are limited by human working hours, AMRs can be programmed to work continuously, leading to increased productivity. Manufacturing plants have successfully adopted AMRs for repetitive tasks such as assembly line operations, allowing human workers to focus on more complex responsibilities that require creativity and critical thinking. This shift not only boosts overall productivity but also enhances employee satisfaction by minimizing monotonous work.

Furthermore, AMRs contribute to improved safety within the workplace. By taking on hazardous tasks and navigating potentially dangerous environments, these robots reduce the risk of workplace accidents, thereby fostering a safer working environment. Industries such as agriculture and construction have reported significant safety improvements by integrating AMRs into their operations, showcasing their versatility and effectiveness in various settings. As businesses continue to embrace technology, the integration of autonomous mobile robots is paving the way for a more efficient, safer, and innovative operational landscape.

Integrating Autonomous Mobile Robots (AMRs) into existing operations can significantly enhance efficiency and productivity in various business settings. To achieve a seamless integration, it is essential to begin with a thorough assessment of your current workflows. Identify repetitive tasks and high-traffic areas where AMRs could be deployed to alleviate bottlenecks and optimize movement. By mapping out these processes, businesses can pinpoint the most beneficial roles for AMRs, ensuring they complement human efforts rather than disrupt them.

Once potential applications are identified, the next step involves selecting the right type of AMR tailored to your specific operational needs. Consider factors such as payload capacity, navigation technology, and compatibility with existing systems. Engaging with AMR manufacturers can also provide insights into the advantages of different models and help businesses choose a solution that aligns with their objectives. Extensive testing in controlled environments before full deployment can aid in fine-tuning AMR functions and addressing any unforeseen challenges.

Training staff to collaborate with AMRs is crucial for a successful transition. Providing thorough education on how the robots operate and how employees can interact with them fosters a harmonious working environment. Encouraging a culture of openness towards technology will help ease any apprehension employees may have regarding robotic automation. As teams become more familiar with AMRs, they can focus on higher-value tasks, ultimately driving innovation and growth within the organization.

The integration of Autonomous Mobile Robots (AMRs) in business operations has become a pivotal strategy for enhancing productivity and achieving significant cost savings. According to a report from the International Federation of Robotics (IFR), the use of AMRs in warehouses and distribution centers can increase overall efficiency by up to 30%. This remarkable improvement is largely attributed to their ability to operate continuously without the fatigue that affects human workers, as well as their capacity to navigate complex environments optimizing pathways to reduce transit times.

In terms of cost savings, a study conducted by McKinsey & Company found that businesses adopting AMRs can lower operational costs by as much as 25%. This reduction is primarily due to decreased labor costs, as AMRs take on repetitive and physically demanding tasks, allowing human employees to focus on more strategic activities. Additionally, the technology behind AMRs minimizes errors in order fulfillment and inventory management, which can further reduce costs associated with returns and lost revenue.

Furthermore, a market analysis by Allied Market Research forecasts that the global AMR market will reach $55 billion by 2026, reflecting a compounded annual growth rate (CAGR) of 26.3%. This growth is driven by the demonstrated ability of AMRs to not only streamline processes but also to adapt to fluctuating market demands, thereby offering businesses a robust solution to remain competitive. Early adopters are already witnessing the transformative effects on their operational frameworks, ultimately leading to greater profitability and sustainability in the long run.

The integration of autonomous mobile robots (AMRs) into business operations is steadily reshaping the industrial landscape. A recent report by the International Federation of Robotics (IFR) indicates that the global market for AMRs is projected to reach $30 billion by 2026, reflecting an annual growth rate of over 20%. This significant increase is primarily driven by advancements in artificial intelligence and machine learning, enabling robots to perform complex tasks with minimal human intervention.

One of the most exciting trends in autonomous mobile robotics is the growing collaboration between robots and human workers. According to a study conducted by McKinsey & Company, organizations that implement a collaborative robot ecosystem can enhance productivity by up to 30%. This not only streamlines operational workflows but also allows human employees to focus on higher-value activities, thus maximizing overall efficiency. As companies continue to adapt to an increasingly automated workforce, the importance of training and equipping staff to work alongside these robots becomes paramount.

Additionally, the shift towards Industry 4.0 is accelerating the adoption of AMRs across various sectors, including warehousing, manufacturing, and healthcare. Research from Gartner predicts that by 2025, 50% of enterprises will be using AMRs for logistics and supply chain operations. This trend highlights the necessity for businesses to not only invest in AMR technology but also to adapt their infrastructure to support these innovative tools. As AMRs become commonplace, their potential to revolutionize operational efficiency will become an undeniable competitive advantage in the marketplace.