14, Raghava Enclave, Transport Road, Secunderabad, Hyderabad (500009)

©2024 All Rights Reserved by excitechrobot.com

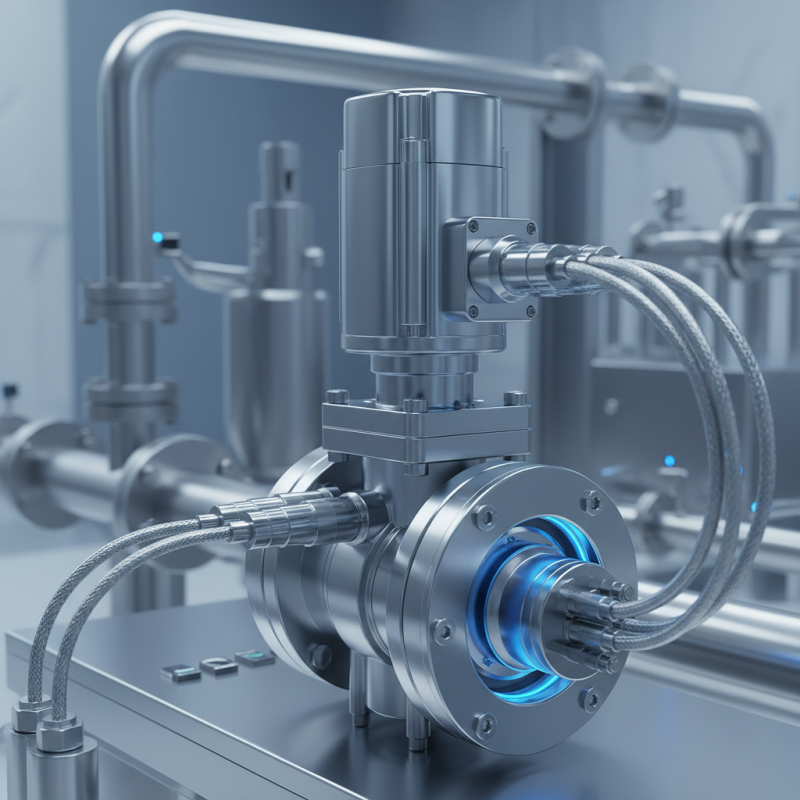

When it comes to fluid control systems, Electric Ball Valves are essential components. These valves offer precision and efficiency in various applications. For industries like water treatment, pharmaceuticals, and food processing, choosing the right electric ball valve is crucial.

In 2026, the market is filled with options for Electric Ball Valves. Selecting one can be overwhelming. You must consider factors such as flow rates, power consumption, and durability. Not all electric ball valves are created equal, and their performance can vary significantly. A poor choice may lead to system failures or inefficiencies.

Different models offer unique features. Some valves are designed for high temperatures, while others excel in corrosive environments. Reflect on your specific needs. Evaluate installations carefully. This guide highlights the best Electric Ball Valves for diverse requirements. It aims to simplify your decision-making process and enhance your operational success.

Electric ball valves are essential components in modern fluid control systems. These valves use electrical power to operate, providing precise control over the flow of liquids and gases. Their design features a spherical disc that allows for quick opening and closing. When energized, the electric motor turns the ball to either permit or prevent flow through the valve.

There are several benefits to using electric ball valves. They offer remote operation, enhancing convenience in various applications. This is particularly helpful in difficult-to-access areas. Furthermore, the responsiveness of electric ball valves ensures quick adjustments. However, installations may require professional guidance. Misalignment can lead to operational issues, and improper wiring can create safety hazards.

Another advantage is their energy efficiency. Once in position, they consume minimal power, which is beneficial for long-term use. It's important to consider the specifications carefully to match the system requirements. Oversizing or undersizing valves can lead to inefficiencies. Thus, careful evaluation is vital. While electric ball valves help streamline processes, awareness of their limitations and installation nuances is crucial.

| Model | Size (Inches) | Voltage (V) | Material | Flow Capacity (CV) | Operating Temperature (°C) | Key Benefits |

|---|---|---|---|---|---|---|

| Model A | 1 | 24 | Stainless Steel | 20 | -10 to 90 | Corrosion resistance, long lifespan |

| Model B | 2 | 120 | PVC | 15 | 0 to 60 | Lightweight, easy installation |

| Model C | 3 | 230 | Brass | 30 | -20 to 120 | High durability, temperature resistance |

When selecting electric ball valves, several key features should guide your decision. One important element is the valve's material. Stainless steel is often recommended for durability and resistance to corrosion. Other materials may not hold up as well in tough environments.

Another feature to consider is the actuator type. Electric actuators come in various styles, including on-off and modulating. Determine your flow control needs. A valve that is too large could lead to inefficient operation. Conversely, a valve that is too small may not facilitate proper flow.

Additionally, assess the control options available. Some valves come with advanced control systems, while others may offer basic functions. The complexity of your application might demand a more sophisticated system. This is an area where many buyers often overlook essential details. It’s crucial to reflect on the specific requirements of your operation, as these choices will impact functionality and longevity.

Choosing the right electric ball valve can be challenging. The market is filled with various options tailored for different needs. When shopping, consider the materials used. Stainless steel valves offer longevity. However, plastic valves may suit corrosive environments better.

Look closely at the features of each brand. Some may provide advanced controls, while others focus on ease of installation. Price often reflects quality, but it's essential not to overlook warranties. A brand with a solid warranty can make a significant difference down the line.

Many users share mixed experiences. Some appreciate robust performance, while others note failures after limited use. Researching online reviews can give insights. However, remember that every valve may have its issues. Balancing features and durability is crucial when making your choice.

When selecting electric ball valves, understanding their applications is crucial. Different industries require varying specifications. For instance, water treatment plants need valves that can handle high flow rates with minimal leakage. On the other hand, chemical processing facilities seek valves resistant to corrosive substances. These specific demands shape design choices and functionality.

In many cases, users may find themselves torn between options. A valve that performs excellently in one situation may fall short in another. For example, a valve designed for minimal space may lack durability under high-pressure conditions. Many specifications seem ideal on paper but may not translate well in real-world applications. It's essential to consider manufacturer guidelines and user experiences to gauge true performance.

Moreover, some electric ball valves may not offer the adaptability needed for changing environments. A valve's ability to function seamlessly across various media is invaluable. Flexibility becomes a significant consideration as industries evolve. Users need to weigh their current needs against potential future requirements. Balancing these factors can indeed be challenging, but it is worth the effort.

Electric ball valves are critical in many industries. Proper maintenance is key to ensuring their longevity. Regular checks can prevent sudden failures. According to industry studies, consistent upkeep can extend the life of electric ball valves by up to 30%. This is not insignificant.

One common issue is debris accumulation. Dirt and particles can obstruct valve operation. Periodic cleaning is essential. It only takes a few minutes but can prevent costly downtime. Inspections of seals and gaskets are crucial as well. Damaged components can lead to leaks. Addressing these issues early can save time and money.

Another factor is temperature fluctuation. Electric ball valves can be affected by extreme temperatures. Ideally, they should operate within a specified range. Keeping track of these conditions is important. Additionally, using the correct lubricants can enhance performance. Not following proper guidelines may lead to premature wear. Over time, adjustments and preventive measures can greatly enhance efficiency.